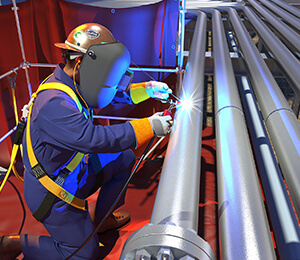

Welding

EMCOR Industrial Services companies will make the connection to move your maintenance event or capital project forward to completion.

We understand what is required for the bond that must occur for the critical components to merge and ensure proper bonding, fit-up, and closure.

The expertise required to enjoin two base metals is challenging:

Performance based trust

- Welding new material to existing

- Restricted access to the work

- Restricted visual of the work

- Environmental influences which impact the weld

- Metallurgy resistance to the bond

- Weld rejection rate < 2% Field) (< 0.5% Shop)

- 800+ approved ASME section IX weld procedures

- AWS Certified Welding Inspectors

Welding Processes

- Shielded Metal Arc Welding (SMAW),(MMA)

- Gas Tungsten Arc Welding (GTAW),(TIG)

- Gas Metal Arc Welding (GMAW),(MIG),(MAG)

- Flux Core Arc Welding (FCAW)

- Submerged Arc Welding (SAW)

- Electroslag Welding (ESW)

Metals

- Aluminum and (Al) Aluminum Alloys

- Carbon Steel and Low-alloy steels (CS, HSLA)

- Chrome Moly Steel (Cr-Mo)

- Stainless Steel (SS) 300 & 400

- Stainless Steel - Duplex

- Copper and Copper Alloys (Cu)

- Copper (Cu)

- Brass

- Silicon Bronze

- Aluminum Bronze

- Copper-Nickel

- Nickel and Nickel Based Alloys:

- Nickel (Ni), i.e. Nickel 200

- Nickel-Copper Alloys, i.e. Monel 400

- Chromium-Bearing Solid Solution Alloys, i.e. Incoloy 825, C-276, Inconel 625, Inco 686, .

- Nickel-Molybdenum Alloys, i.e. Hastelloy B-2

- Precipitation-Hardening Alloys, i.e. Inconel 718/725, Monel K-500.

- Titanium (Ti)

- Zirconium (Zr)